How to Choose the Right Sump Pump Check Valve for Your Home Needs in 2025

When it comes to protecting your home from flooding and water damage, choosing the right sump pump check valve is crucial. As we approach 2025, advancements in pump technology mean that homeowners have a wider selection of options than ever before. According to renowned plumbing expert John Smith, “The right sump pump check valve not only improves the efficiency of your pump system but is essential in safeguarding your property against unexpected water influx.”

In this context, understanding the nuances of various check valve types, their compatibility with different sump pump models, and the specific needs of your home is vital. With the right guidance, homeowners can make informed decisions that will enhance the performance and reliability of their sump pump systems. This article will explore the key factors to consider when selecting a sump pump check valve, ensuring your home is better equipped to handle any water challenges that may arise in the future.

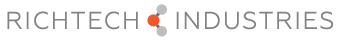

Understanding Sump Pump Check Valves: Types and Functions

Sump pump check valves are essential components that help maintain the efficiency of your sump pump system. They prevent water from flowing back into the sump basin once it has been expelled, ensuring that your home remains dry during heavy rains or flooding. Understanding the different types of check valves available is crucial for selecting the right one for your needs. The main types include flapper valves, spring-loaded valves, and inline valves, each offering unique advantages in terms of performance and maintenance.

When choosing a sump pump check valve, consider factors such as the size of your plumbing and the type of sump pump you have. It's vital to select a valve that matches your sump pump’s discharge pipe diameter to ensure a proper fit. Additionally, be mindful of the material used in the check valve, as options like PVC and stainless steel provide varying levels of durability and resistance to corrosion.

Tips: Regular maintenance of your check valve can prolong its lifespan. Periodically inspect it for signs of wear or damage, and ensure that it's functioning correctly by testing the valve after heavy usage. Additionally, consider installing a valve with a larger spring if you live in an area with frequent flooding, as this can provide enhanced reliability against backflow issues.

Factors to Consider When Selecting a Check Valve for Sump Pumps

When selecting a check valve for your sump pump in 2025, several factors should be at the forefront of your decision-making process. First and foremost, consider the valve's material and design. High-quality materials, such as PVC or cast iron, are essential for ensuring durability and resistance to corrosion. Additionally, the valve should have a design that allows for smooth water flow, preventing any blockage that could hinder the pump's performance.

Another important factor is the size and compatibility of the check valve with your existing sump pump system. Ensuring that the valve matches the pipe diameter and is compatible with the type of pump you have will enhance efficiency and minimize potential leaks or failures. It's also wise to look for features such as a spring-loaded mechanism, which can provide better sealing and reduce the risk of backflow, thereby protecting your pump and keeping your basement dry even in heavy rain or flooding situations. Opting for a check valve that has been tested and proven effective in real-life scenarios, like those used in flood-prone areas, can also guarantee reliability when you need it most.

Comparing Different Sump Pump Check Valve Materials and Durability

When selecting a sump pump check valve, the material and its durability are critical factors to consider. Common materials include PVC, rubber, and brass. According to a report by the American Society of Home Inspectors, valves made from PVC tend to be lightweight and resistant to corrosion, making them a popular choice for homeowners. However, they may not withstand extreme temperatures or heavy-duty applications as effectively as other materials. In contrast, brass check valves, while more expensive, offer superior durability and can endure higher pressures, along with a longer lifespan, as indicated by a study from the National Association of Home Builders.

Rubber check valves provide a flexible option, often chosen for their ability to create a tight seal and minimize water hammer effects. Research by the International Association of Plumbing and Mechanical Officials shows that rubber valves can significantly reduce noise and vibrations in the plumbing system, enhancing overall comfort in the home. As homeowners assess their sump pump needs in 2025, understanding the advantages and limitations of different materials will enable them to make informed decisions, optimizing both the functionality and longevity of their sump pump systems.

How to Choose the Right Sump Pump Check Valve for Your Home Needs in 2025 - Comparing Different Sump Pump Check Valve Materials and Durability

| Material | Durability (Years) | Corrosion Resistance | Weight (lbs) | Cost ($) |

|---|---|---|---|---|

| PVC | 10+ | Good | 1 | 15 |

| Brass | 15+ | Excellent | 2 | 30 |

| Cast Iron | 20+ | Fair | 5 | 45 |

| Stainless Steel | 25+ | Excellent | 3 | 60 |

| Plastic | 5+ | Good | 0.5 | 10 |

Common Issues with Sump Pump Check Valves and How to Avoid Them

When selecting a sump pump check valve, it's essential to be aware of common issues that can arise and how to avoid them. One prevalent problem is the occurrence of backflow, which can undermine the effectiveness of your sump pump. This often happens when a check valve fails to seal properly. To mitigate this issue, you should choose a high-quality valve with a robust sealing mechanism and regularly inspect it for wear and tear.

Another concern is the accumulation of debris within the valve. Over time, dirt and sediment can clog the valve, hindering its function. To prevent this, consider installing a valve with a built-in strainer, which helps filter out debris before it reaches the valve. Additionally, regular maintenance, including cleaning and inspecting the valve and surrounding area, can significantly reduce the risk of clogs and ensure your sump pump operates efficiently.

Maintenance Tips for Ensuring Optimal Performance of Your Check Valve

To maintain the optimal performance of your sump pump check valve, regular maintenance is essential. Start by inspecting the valve for any signs of wear or damage. Look for cracks, corrosion, or debris buildup that could hinder its operation. Cleaning the valve periodically helps prevent clogs and ensures smooth functioning. Use a soft brush or cloth to remove any accumulated dirt, and rinse it with clean water to avoid residue.

Another important aspect of check valve maintenance is checking for proper sealing. An effective check valve should prevent backflow, so ensure that it closes tightly after the sump pump stops running. To test this, observe the valve during operation. If you notice any leaks or the valve failing to close completely, it may require replacement. Additionally, lubricate moving parts as necessary to minimize friction and prolong the valve’s lifespan, and always refer to the manufacturer’s guidelines for specific maintenance recommendations tailored to your model. Regularly assessing and caring for your check valve can significantly enhance the efficiency of your sump pump system.

How to Choose the Right Sump Pump Check Valve for Your Home Needs in 2025

This bar chart illustrates the importance of various factors when selecting a sump pump check valve. The factors include material quality, flow rate capacity, installation ease, maintenance frequency, and cost efficiency, all rated on a scale from 1 to 10. Focus on these priorities to ensure optimal performance of your check valve.

Related Posts

-

Understanding Sump Pumps in Basements: Key Statistics and Trends for Homeowners in 2023

-

10 Best Drainage Pipe Solutions: Enhance Efficiency by 30% and Reduce Flood Risks

-

Understanding Sump Pump Check Valves: Essential Maintenance Tips for Optimal Flood Protection

-

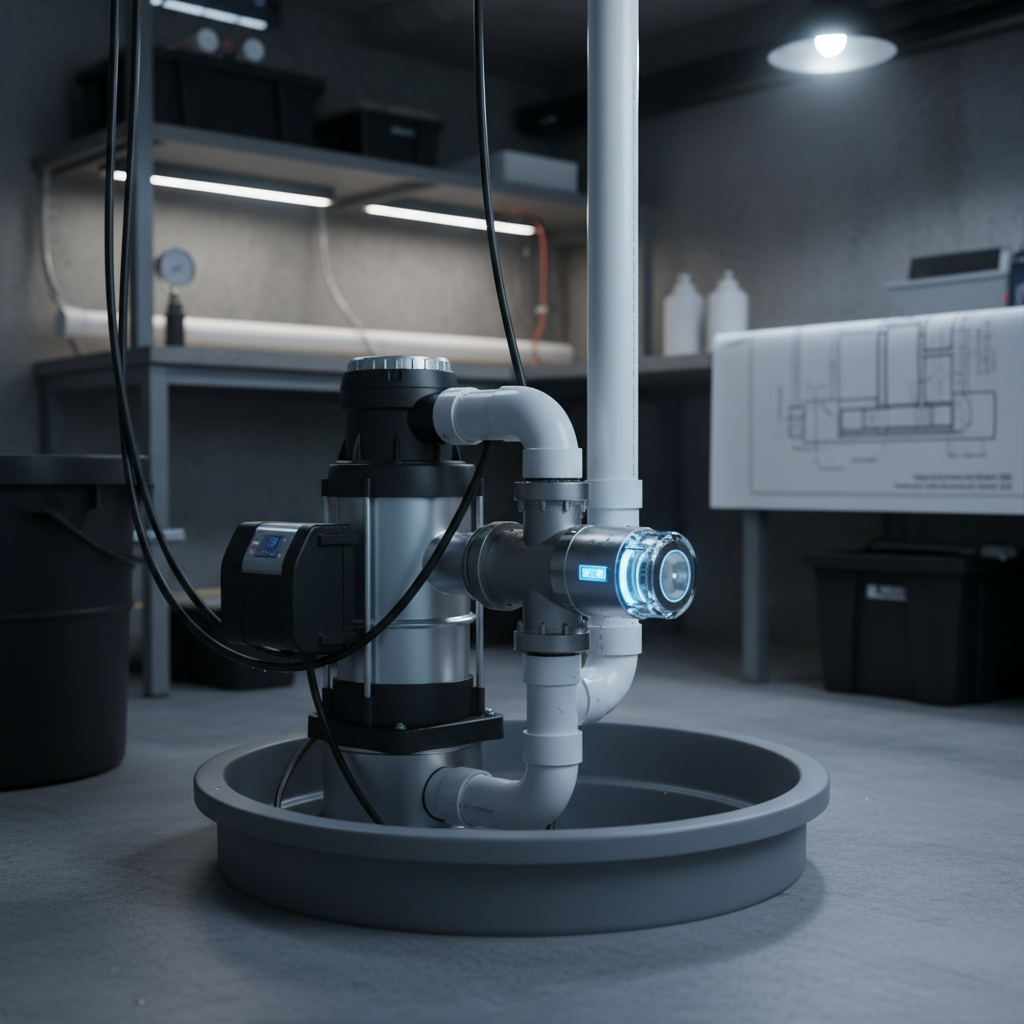

Understanding the Importance of Sump Pump Float Switches for Home Water Management

-

Top 10 Basement Water Solutions to Prevent Flooding in 2025

-

Top 5 Backup Power Solutions for Sump Pumps to Prevent Flooding