How to Choose the Right Float Pump for Your Needs?

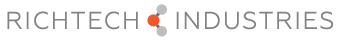

Choosing the right float pump can be a daunting task. With various models and features available, making an informed decision is crucial. John Smith, a well-known expert in the float pump industry, states, "Selecting the ideal float pump can significantly impact efficiency." This highlights the importance of understanding your specific needs.

When considering a float pump, assess the application and environment. For example, a residential pond may require different specifications than an agricultural setup. Look at factors like pump capacity, power source, and material compatibility. Understanding these elements can help you avoid costly mistakes and ensure effective operation.

Many people overlook small details. An underrated aspect is the weight of the float pump. A lighter model may be easier to transport but could compromise durability. Reflecting on your specific circumstances is essential. The ideal float pump for one person may not fit another. Take time to research and evaluate your options carefully.

Understanding Float Pumps: Types and Applications

Float pumps are versatile tools used in various applications. Understanding different types can help you choose the right one. There are submersible and non-submersible float pumps. Submersible pumps work underwater, making them ideal for deep wells. Non-submersible float pumps sit above the water, better for shallow jobs.

When selecting a float pump, consider the job's requirements. Look at the water’s depth and flow rate. Some pumps can handle debris and solids, while others cater to clean water. Matching your pump to your specific needs is crucial.

**Tips for Selection:**

1. Evaluate the environment. Is it muddy or clean?

2. Check power supply options. Electric or gas?

3. Look for maintenance features. Easy to clean is better.

Remember that a pump’s efficiency can fade over time. Regular checking helps maintain performance. Think about how often you'll use it. Investing in a durable pump might save money in the long run. But not all pumps are equal. Some may need extra attention more than others.

How to Choose the Right Float Pump for Your Needs?

| Type of Float Pump | Application | Maximum Flow Rate (GPM) | Power Source | Key Features |

|---|---|---|---|---|

| Submersible Float Pump | General water transfer | 50 | Electric | Portable, Easy to use |

| Engine-Driven Float Pump | Construction site dewatering | 100 | Gasoline | High flow, Durable |

| Hydraulic Float Pump | Flood relief | 200 | Hydraulic | Robust, Efficient |

| Solar-Powered Float Pump | Remote water supply | 30 | Solar | Eco-friendly, Low maintenance |

Key Specifications to Consider When Selecting a Float Pump

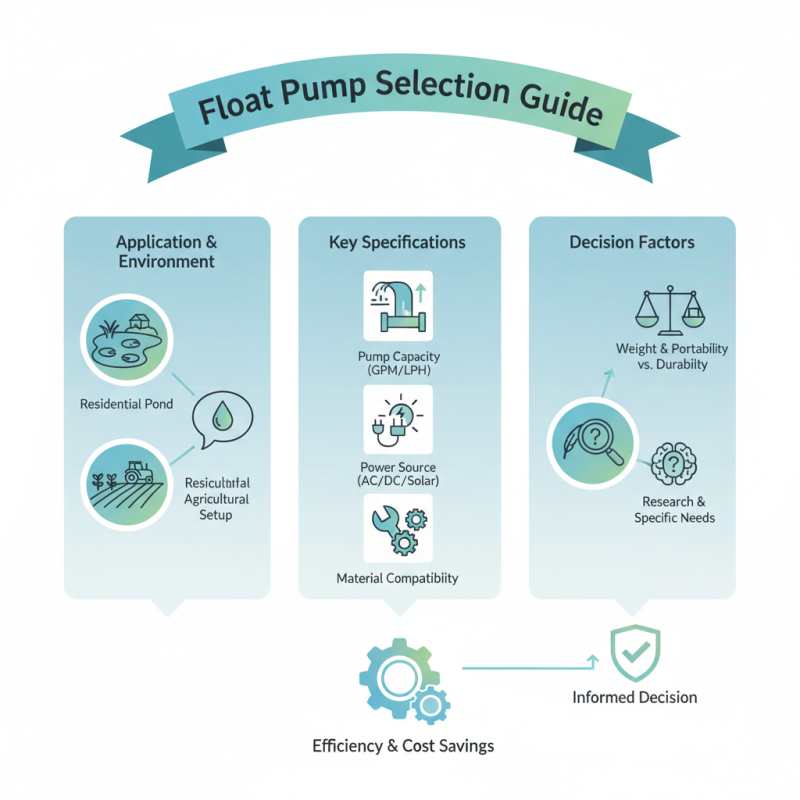

When selecting a float pump, focus on key specifications that affect performance. One critical aspect is the pump's flow rate. This measures how much water the pump can move per minute. Generally, a flow rate of 20 to 50 gallons per minute is adequate for small-scale applications. However, larger projects may require pumps with higher capacities, sometimes exceeding 100 gallons per minute.

Another essential specification is the maximum head height. This is the height from which the pump can lift water. A good float pump should handle heights of 15 to 35 feet for most yard and construction tasks. Always check if the pump can adapt to your specific needs.

Tip: Consider the power source. Electric pumps offer convenience but might need a power supply nearby. Gasoline-powered pumps offer mobility for remote sites.

Additionally, examine the pump's construction material. Durable materials resist corrosion and wear. Rubber and stainless steel are popular options in the industry. Reports suggest that high-quality pumps can last up to five years with proper maintenance.

Tip: Regular maintenance can prevent costly repairs. Inspection every few months keeps the pump in good working order. Remember, choosing the right float pump is about balancing performance specifications with your unique requirements.

Analyzing Flow Rate Requirements for Your Specific Use Case

Choosing the right float pump begins with understanding flow rate requirements. Flow rate refers to the amount of water the pump needs to move per minute. Assessing your specific use case helps in determining this requirement. For example, a construction site may need a higher rate than a residential garden.

Consider the volume of water. For small ponds or landscaping, a lower flow rate suffices. However, larger bodies of water demand more power. Think about how fast you want to empty or refill a space. This timeline can influence the flow rate you select.

Don’t forget other factors, like head height. This distance affects pump performance. If your pump has to lift water higher, flow rates may drop. People often overlook this detail. It's essential, as it directly impacts efficiency. Evaluating your situation can be tricky. It requires analysis and sometimes, trial and error.

Assessing Material Durability and Compatibility in Float Pumps

Choosing the right float pump involves understanding material durability and compatibility. Construction materials greatly influence performance. For instance, pumps made from thermoplastic can resist corrosion better than metal options. Data shows that corrosion can decrease pump efficiency by 30% over time. Selecting a durable material is crucial for longevity.

Additionally, compatibility with the liquids you handle cannot be overlooked. Pumps that can’t withstand specific liquids may fail. If you use harsh chemicals, for example, a standard rubber seal might degrade quickly. Research indicates that using the wrong material can lead to pump failures, costing businesses significant downtime.

Keep in mind that not all materials perform equally. Some may react poorly to certain conditions. Conduct thorough testing in real-world scenarios. Always consider the specific needs of your application before making a choice. This ensures reliability and efficiency in your operations.

Material Durability and Compatibility in Float Pumps

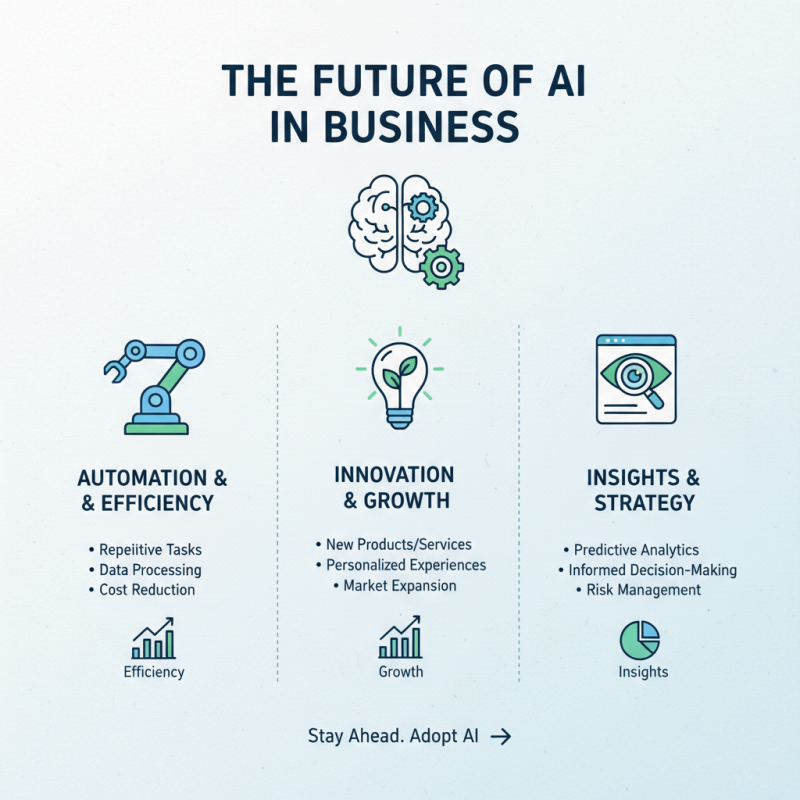

Evaluating Energy Efficiency and Operational Costs of Float Pumps

When selecting a float pump, energy efficiency and operational costs are key factors. Look at the pump's power consumption. A lower wattage might seem ideal, but it needs adequate flow rates.

Tips: Consider your water source. Is it clean or does it contain debris? This influences pump choice significantly. Dirty water requires a more robust model, even if it costs more.

Operational costs are not just about energy use. Maintenance adds up too. Regular checks can help avoid unexpected breakdowns and expenses. Always factor in these hidden costs.

Tips: Check if the pump has easy-access filters. Clogged filters can lead to higher energy use. Choose models that offer simple maintenance options to save time and money.

Related Posts

-

Essential Guide to Choosing the Right Basement Water Pump System for Your Home

-

Top 10 Tips for Choosing the Best Basement Waterproofing Systems

-

Understanding Sump Pumps in Basements: Key Statistics and Trends for Homeowners in 2023

-

Top 10 Benefits of Sump Pump Backup System for Home Protection

-

Top 10 Basement Water Solutions to Prevent Flooding in 2025

-

Understanding the Importance of Basement Waterproofing Systems for Home Protection